A sofa, a coffin and a stackable multipurpose cube are among the many many objects that had been displayed in Add Picket, an exhibition exploring the potential of recyclable and biodegradable 3D-printed timber.

Designers Esmée Willemsen, Janek Beau, Friedrich Gerlach and Julia Huhnholz created 4 separate initiatives using EconitWood, which is produced by German agency Additive Tectonics.

The material is made by combining leftover wood from sawmills and timber harvesting with a pure, non-toxic and flame-retardant magnesium carbonate binder, and its extrusion by way of 3D-printing permits for the creation of sophisticated shapes with out producing any waste.

Willemsen wanted to reap the advantages of the made-to-order nature of 3D printing collectively together with her design, a coffin known as Finalform.stl. Her imaginative and prescient is that the design might probably be printed with variations for varied our our bodies, whereas moreover incorporating personalised decoration at minimal extra value.

She moreover wanted to chop again the environmental impression of burials by eliminating the metal grips, screws and completely different non-timber components that could be current in a typical coffin, and doubtless by adapting the design to optimise decomposition inside soils at completely completely different locations.

“Using 3D printing as a result of the manufacturing methodology felt like a pure match for this enterprise,” acknowledged Willemsen. “The flexibleness of this course of permits for adaptation to completely completely different physique kinds and sizes, which is popping into increasingly important as larger-scale coffins develop in popularity.”

“Standard coffins – these lined with paint or added metals or plastics – can negatively impression the soil over time, so using a material that helps larger decomposition and filtration felt like a vital step forward,” she continued.

“EconitWood moreover opens up prospects for adapting the coffin’s density and filtration properties to specific soil circumstances, making the design far more attentive to environmental desires.”

Gerlach oriented within the course of creating primarily essentially the most atmosphere pleasant use of the 3D-printing course of in his design, the Lumo sofa. The sofa has an EconitWood shell that is stackable in manufacturing to maximise printer mattress space.

“I centered on one key attribute of this 3D printer: it doesn’t truly matter whether it is printing a single small object or a whole big block in a single job — every take roughly the an identical time period,” acknowledged Gerlach. “Attributable to this, I decided to design an object that might probably be successfully stacked contained in the printer’s assemble amount, thereby rising its normal printing effectivity.”

“This technique would possibly make the strategy additional attractive to companies, as improved effectivity helps lower manufacturing costs. I moreover wanted to indicate the printer’s functionality, displaying that it’s doable to print large-scale furnishings gadgets with none factors.”

The Lumo sofa is achieved with a removable materials suspended seat that attaches to a groove alongside the shell’s edge, and since every the upholstery and filling are 100 per cent wool, the sofa in its entirety would lastly biodegrade if returned to the earth.

Whereas many wood composite provides are made with a plastic binder, EconitWood’s is a pure and non-toxic mineral binder that it says would dissolve in water after some years throughout the pure environment, and the untreated wood would rot away. However, the company’s hope is that the merchandise have a protracted life or be returned to the company for recycling.

Huhnholz moreover designed for optimum effectivity collectively together with her piece, a shelving unit titled Offset. The unit is made up of three straightforward and sculptural EconitWood posts, which have a conical kind designed so that the segments may very well be nested inside each other all through manufacturing and additional may very well be made in a lot much less time.

To assemble the shelf the segments are merely stacked and achieved with laser-cut aluminium plates.

“The Offset shelf was impressed by the considered reinterpreting a traditionally picket object using the distinctive properties of printed wood,” acknowledged Huhnholz. “The assembly of picket poles and aluminium boards relies upon solely on precise geometric interlocking. The material’s textured ground required numerous iterations to achieve the proper match.”

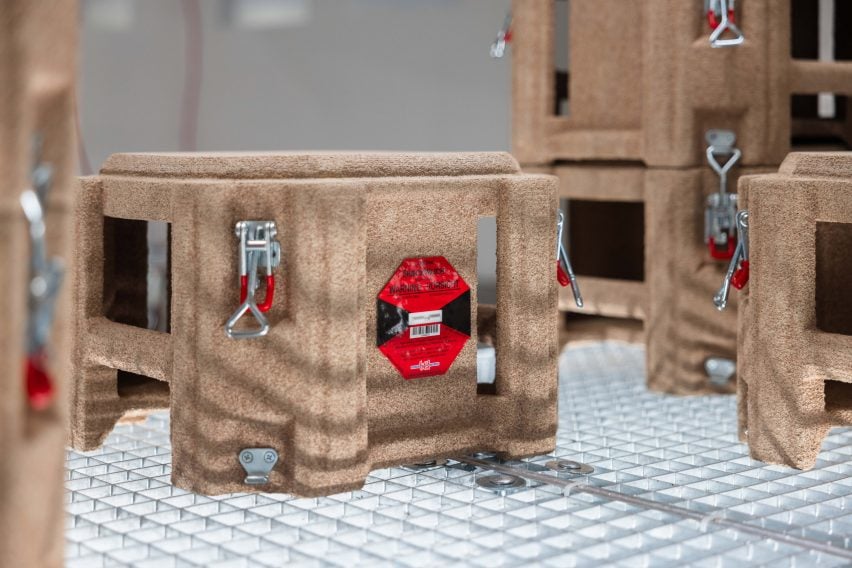

Beau checked out effiency from a definite angle alongside along with his Sandbox stool, which turns right into a multifunctional and modular furnishings decision if utilized in multiples, with two modules creating the height of a chair and three the height of a desk.

The modules may be shipped with out packaging as the dimensions have been optimised to regulate to most supply restrictions, with six modules changing into side by side on a pallet.

“I was notably desirous about exploring shapes that are generally prevented in wood manufacturing due to their complexity or inefficiency,” acknowledged Beau. “My goal was to create a furnishings piece that is simple to take care of and may very well be shipped successfully. This led me to evaluation outdoor cases, which galvanized the design of my object.”

Willemsen, Beau, Gerlach and Huhnholz exhibited their EconitWood designs at Designblok in Prague, Czech Republic in October 2024. The 4 designers had been Designblok Diploma Alternative winners in 2023, giving them the possibility to exhibit on the 2024 event.

As a substitute of doing solo shows, the quartet banded collectively and approached Additive Tectonics a few collaboration using EconitWood. Their exhibition, Add Picket: Views on Printable Timber, gained the 2024 Designblok Award for Best Designer Presentation.

Totally different experiments with 3D-printed wood have included the Warp teahouse pavilion, which was made out of shaped tiles by architects Kei Atsumi and Motoya Iizawa.

Designblok occurred from 2 to 6 October 2024. See Dezeen Events Info for an up-to-date file of construction and design events taking place world vast.